The use of reinforcing mesh helps to preserve the strength of the plaster on the facade of the building

Content

- 1 Why use a reinforcement grid?

-

2 The main types of mesh under the plaster walls

- 2.1 Metal grid

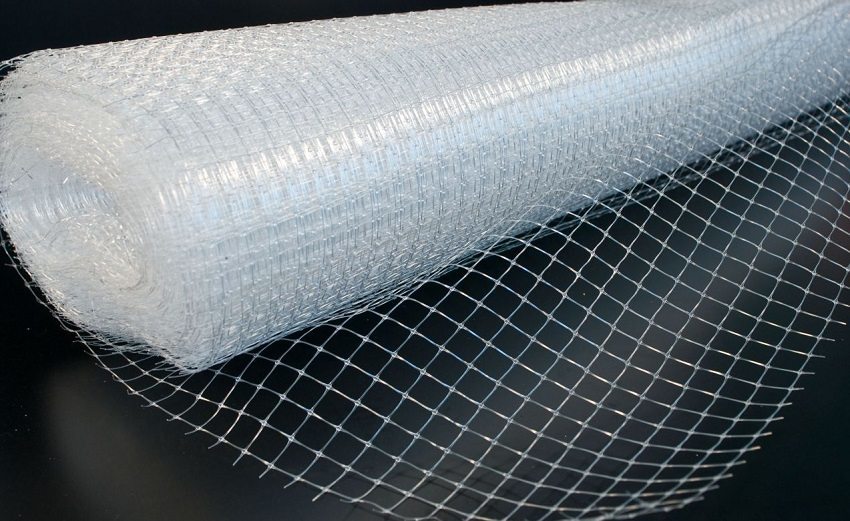

- 2.2 Glass cloth mesh

- 2.3 plastic mesh

- 2.4 polymeric grid

- 3 What mesh for reinforcement choose?

Why use a reinforcement grid?

Reinforcing mesh with exterior wall plastering used in case of finishing a weak adhesion to the main material components wall material (concrete, aerated concrete, brick or wood). In such cases, there is a possibility of peeling and crumbling like plaster some time after application of the solution, and immediately. Furthermore, the mesh reinforces the rough planarization layer.

The need to use reinforcing mesh arises in the finishing works in the newly constructed building, where the walls still shrink. Deformations facade occurring during shifting of lead to cracking and disruption of the integrity of the finish coat.

Reinforcing mesh in the regeneration wall "pie"

What mesh used to plaster walls - depending on the material of the walls, their topography, degree of wear, from availability of external insulation, the layer structure and thickness of materials, finally, on the climatic conditions. But today a wide range of reinforcing mesh plaster walls must meet certain requirements:

- ease;

- absence of additional loads on the structural elements;

- resistance to aggressive chemicals and corrosion resistance;

- tensile strength coupled with elasticity;

- resistance to various types of loads;

- density in the range 150-170 g / m2 (To provide strength and elasticity at the same time).

wall insulation system "wet facade"With reinforcing mesh

The main types of mesh under the plaster walls

The diversity of modern building materials, adhesives and leveling mortars, the use of different additives and additives in their composition led to the expansion of the reinforcing range products.

The main varieties of nets for plaster walls are distinguished by their material composition:

- metal;

- Glass cloth;

- plastic;

- polymer.

The use of reinforcing mesh helps prevent cracking plaster shrinkage building

Metal grid

By reinforcing metal mesh for plaster facade walls resort in cases where the thickness of the finish solution reaches 30 mm or more. If plaster plan apply as thin a layer as the reinforcing layer is applied to the walls of the mesh polymeric, plastic or fiberglass.

Useful advice!By itself, a metal mesh for plaster walls are not available for use in areas with high humidity or exterior trim. Here it is advisable to use the mesh of galvanized or plastic protection.

Securing the front grid to start with areas that are difficult to handle: the corners of window and door slopes

There are four main types of metal reinforcement differing embodiments and applications of production technology.

woven mesh

It is flexible and lightweight design, woven from very thin and strong wires of different sections. When finishing facade is applied as a grid for plaster walls - galvanized, with mesh size of 1 by 1 cm. Ease of implementation of forms: in large rolls - makes it possible to use it for their own work performed.

Woven wire mesh

Mesh netting or braid

Mesh netting - steel braided design with a mesh size of 2 by 2 cm, used to strengthen the wall or facade with stucco coating large areas. Topical by applying a layer thickness of 30 mm and above. For outdoor applications or in areas with high humidity is used galvanized netting. Due to the mobile system node is particularly advantageous for the walls, which material is compressed or expands with changing weather conditions (temperature and humidity), i.e. for wooden walls or from aerated concrete.

The mesh netting is used, the substrate layer plaster over 30 mm

welded wire mesh

In the manufacture of welded wire mesh overlaid on each other perpendicularly, and is welded at the joints, thereby forming square cell. Wire it uses galvanized or treated with a protective polymer composition. This reinforced structure can be used to strengthen the plaster facade of buildings exposed to heavy rainfall: new buildings or located on the ground moving - as well as the walls of the aerated.

Welded mesh reinforcement is used for new buildings walls

The best results with prevention of topcoat cracking manages achieved with welded mesh for plaster wall facade with a mesh size of about 2.3 cm. This material is marketed packed in meter wide rolls.

Expanded metal mesh

In the case when the surface of 1 square meter assumes a low flow rate of the solution, it is preferable to take the expanded metal mesh for plaster exterior walls.

Such a mesh with diamond-shaped cells derived from the metal sheet after the punching of holes in it of the same size, staggered, and then stretching the resulting preform.

Types and sizes of expanded metal mesh

Glass cloth mesh

Along with metal for reinforcing mesh plaster walls are used as products of synthetic materials: polymers, fiberglass, plastic.

Glass cloth netting is considered universal. Its web being made of glass without alkaline impurities in conjunction with aluminum as an additional component, has a high mechanical strength. Due to this, in the plaster layer withstand a large thickness (from 30 to 50 mm). In addition, a grid of glass resistant to chemical and biological influences, in particular to the processes of putrefaction.

fiberglass - an effective tool against cracking plaster

Widely used for the reinforcement of the walls of almost all - especially of aerated concrete, foam blocks, brick - with thermal insulation of most materials.

plastic mesh

Plastering walls of brick and aerated concrete more often used plastic mesh, which is best suited for use in heat-insulating layers of foam or Penoplex.

A grid of fiberglass is resistant to chemical and biological attack

It is important!Plaster for the foam in most cases is made based on cement (which is alkaline reaction), respectively, for fixing a plastic grid select blend resistant, alkalis.

Plastic mesh plaster walls of aerated withstand temperature extremes from -40 to + 100 ° C. Perform fine mesh reinforcing walls, grid with large cells - the facade and basement of the building.

Plastic nets are different cell value

polymeric grid

The polymer mesh may be called a new word in reinforcing materials. Undoubted advantages of reinforcing webs are light weight, chemical resistance (particularly - to the action of alkalis) and corrosion, elasticity and flexibility.

Heavy-duty variants of this type of mesh used in the construction of roads and bridges, as able to keep the burden of heavy cement compositions. Flexibility and elasticity allow the use of plastic nets for reinforcement complex relief structures: arches, doorways, bevels.

Polymer mesh resistant to chemical attack, which is very important in the case of a finishing solution with an alkaline medium

Grids of polymers do not hinder the spread of the magnetic field, due to which are indispensable in the finishing work on live communications.

Related article:

|

Polymer networks - one of the best solutions for reinforcing plaster walls and facades of most of the existing materials: bricks, silicate blocks, foam concrete, aerated concrete.

What mesh for reinforcement choose?

The range of currently produced reinforcing materials is very wide, with the majority of them are fairly universal.

Polymer networks - the optimum solution for reinforcing plaster walls and facades of most of the existing materials

Useful advice!Securing the front grid to start with areas that are difficult to handle: with angles, arches, window and door slopes, as well as areas with embossed details.

This daily articles about building and repair, construction of apartments and a country house. Useful information with interesting ideas and step by step instructions.

The reprint of materials from the site is possible only if the first paragraph of text directly indexed hypperlink on the page with the original article on remoo.ru