Plaster on expanded polystyrene, aerated concrete, gas silicate and other materials

Table of contents

- 1 Plaster work on expanded polystyrene

- 2 Work on the aerated concrete and gas silicate

-

3 other work materials

- 3.1 Paint

- 3.2 Metal

- 3.3 OSB

- 4 Summing up

Finishing insulated buildings designed to protect the insulating material from the external environment.

The most common way is a plaster for finishing polystyrene foam, or foam on top of concrete blocks.

In any case, the plaster of the insulant is a specific process, characterized by applying the technology of conventional composition.

In any case, the plaster of the insulant is a specific process, characterized by applying the technology of conventional composition.In order to qualitatively decorate wall insulation, should be used as a solution for high-quality plaster and the right technologies for their application.

In this article we look at some aspects of the process. We hope that the recommendations that are given below will help you to effortlessly cope with the application of the plaster on the walls with his own hands.

So, first try to understand - like plastering polystyrene.

Plaster work on expanded polystyrene

Plaster of polystyrene foam insulation protects against mechanical influences, UV radiation, temperature differences. To finish on a polystyrene-based materials special mixes available.

They are used for gluing the mesh and to create the alignment of the base layer to which is applied a decorative plaster or exterior paint.

The sequence of finishing polystyrene cladding:

- Paste over the entire surface of a mesh size of 5x5 mm cell. For gluing the mesh to polystyrene universal composition layer is applied 2-3 mm thick. Then, gradually rolling nets roll, glue it to the composition so that the edges of the roll was about 5 cm not glued grid. These gaps we use to form adjacent strips joints.

Fixing the grid (the price - from 120 rubles).

Note! Grid for polystyrene foam must be resistant to alkalis.

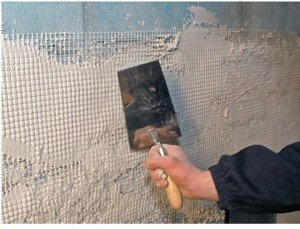

- Mesh smooths metal spatula or trowel, pushing it into the interior of the composition.

- Before plastering of slopes and angles of buildings they should stick the grid (this is more convenient to use a band width of about 30 cm) or special perforated metal block area.

- After all papered plane grid, proceed to its grout. Pointing should only be dried mixture.

- Grout is carried out using a plastic float, which is fixed on the emery cloth.

Grout mesh with their own hands

- Nipped by grid alignment can be carried out plaster walls. To form the alignment layer using the same composition as that for the gluing of the grid.

- Leveling plaster of expanded polystyrene applied using a wide spatula layer 2-3 mm thick.

- After the planarization layer is applied, the coating must dry for 1-4 days. Grout is carried out by the above technology.

- Iced area gruntuem then can begin to spray finishing layer - decorative plastering or painting.

finishing

Work on the aerated concrete and gas silicate

Aerated concrete and gas silicate blocks due to its characteristics are considered to be long enough one of the most popular materials for the construction of residential houses.

Plaster walls of aerated material designed to protect against moisture. This means that choosing than plastering concrete, we must first of all pay attention to the water-repellent properties of mixtures. It is important to keep in mind that coverage for such surfaces must have significant vapor permeability coefficient.

The process of finishing surfaces of porous materials (aerated and gazosilikata):

- The cleaned surface is treated with primer. For walls of aerated primer must necessarily contain hydrophobicizing (water-repellent) component. water-repellent layer to be superfluous silicate blocks.

- On the surface anchoring ogrutnovannoy alkali resistant fiberglass mesh.

- On top of the fixed stacks with a spatula and trowel applied a special mass. It is best to use a mixture designed specifically for work on aerated concrete and gas silicate, their Features not only provide high-quality adhesion of the substrate, but also significantly extend the life of operation.

The plaster on the grid

- Applying a layer of 5-9 mm.

- For silicate structures of aerated concrete blocks and is mandatory application of paint layer protecting a surface from external influences.

other work materials

As with stucco exterior and interior walls, you may be faced with situations that are practically not described in the literature. For example, quite often there is a question whether the paint on the plaster can be?

Paint

As practice shows, optionally completely abate ink layer "zero". If you are using the qualitative composition of the painted surface will be enough to put on her several hundred deep cuts per square meter.

Metal

The problem may also be a plaster on metal. To decorate the exposed beams or channels, they are sufficient to treat the surface of the granular type primer Ceresit CT 16.

OSB

And it is really a trivial task can be plaster on OSB (oriented strand board).

The thing is that when installing the CAP between the plates sure to leave expansion gaps that before applying the composition must be filled with silicone sealant. Another option - the overlap of 5 mm polystyrene plates.

Summing up

As a result, we can state with full responsibility that the plaster on polystyrene or aerated concrete is not anything not feasible. It is enough to prepare thoroughly, make diligence - and you will succeed! We hope our article has been helpful to you. In order to more accurately understand the technological and practical issues on our website provides detailed photo and video instruction, in which you will find the necessary information on the question.