Belt foundation is the most common because of its versatility for most types of soil and the ability to withstand a large weight of buildings. Its construction is quite labor-intensive, and involves mandatory reinforcement - reinforcement of concrete with metal structures. It is intended to compensate the action of forces aimed at compressing and stretching concrete, preventing its destruction due to temperature fluctuations and high loads.

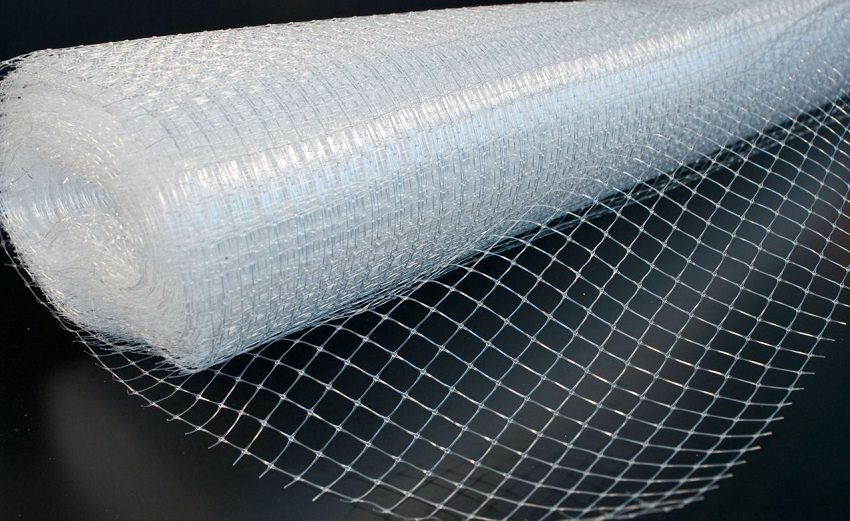

For reinforcement a special rod is used with a ribbed surface from 6 to 32 mm in diameter. Requirements for its installation depending on the type of soil, structure, thickness of the reinforcement are described in SNIPs and are mandatory for compliance not only with large construction contractors, but also with the independent erection of the house.

Rules for installation of fittings

For private 1-2 storey houses, the most commonly used reinforcement is 10-12 mm( possibly composite), laying it at the top and bottom of the basement. The upper and lower layers are connected by vertical supports in steps of 50-80 cm, which have a small load. The diameter of vertical reinforcement can be less, 6-8 mm.

Horizontal bars, the distance between which should not be more than 30 cm, stack with overlapping, linking them with vertical. In each layer there are 2-4 twigs. For a shallow basement, two layers are sufficient, three deep ones.

For protection against corrosion, the valve must be completely immersed from above in concrete. From the formwork it should also be separated by a layer of 6-8 cm. The most common way of fastening reinforcing bars is by using a wire and a crochet hook. Welding is used only for certain types of reinforcement.

Step-by-step reinforcement technology

Valve installation can be divided into two stages. Initially, a wire frame is assembled in the exact size of the trench under the future foundation and in accordance with the calculated load. It can be collected in stages, using a long workbench, accrued with the help of planks for the entire length of the rods. In the beginning, more thin vertical rods of the required length are harvested and assembled with wire in racks.

Then, on the thicker reinforcement that is laid out on a flat surface, these posts are fastened with a knitting wire approximately every 30 cm. So the lower horizontal belt of the reinforcement is ready. The upper one is executed in the same way.

Special care must be taken when binding the reinforcement to the corners, so that the sides of the foundation are tightly connected. The individual parts of the reinforcing cage at the corners are strengthened by L-shaped elements, with a side not less than 40 cm. Vertical posts at the corners should be located twice as often as on the main part.

After the formwork is ready for the foundation( how to do it, read here), you can proceed to the next stage - laying the finished reinforcement frame and pouring concrete. Before pouring concrete, it is necessary to lay pipes for communication and ventilation through the bars of the pipe fittings. For a more even distribution, the concrete must be poured in layers, each of which must be leveled by a vibrating platform or carefully by hand. After drying, a waterproofing of the whole foundation is made with a ruberoid or bitumen mastic, according to the technology described here.

The strength and durability of a house depend directly on the proper laying of the foundation and its strengthening. This crucial stage of construction is best entrusted to professionals who will perform laborious stages in pouring and reinforcing the foundation properly. Independently to undertake this process costs only at presence of experience and confidence of own forces.

How to knit armature, you can look at the video: